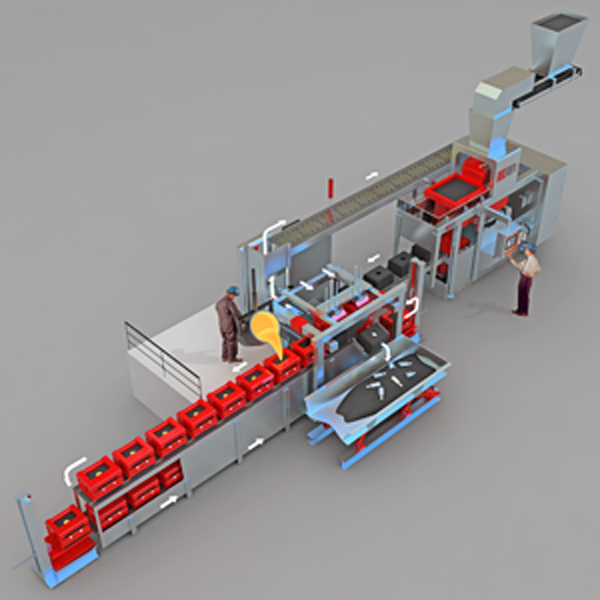

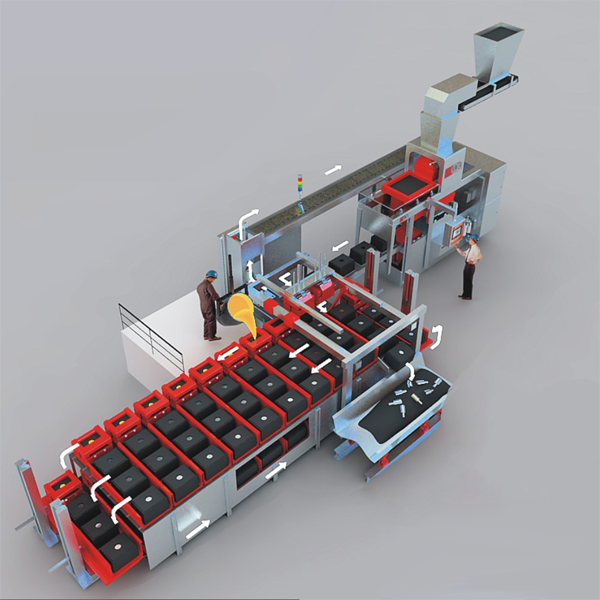

No matter what type of molding machines you run, you can’t maximize production unless mold handling, transport, pouring and cooling operations prior to shakeout seamlessly and precisely match them. That’s why we design our mold handling systems to meet each customer’s exact equipment, production and foundry floor specifications…and why they’re used with all types of molding machines, all over the world. Our patented HLH linear mold handling systems are economical, efficient, easy-to-install, and feature a boardless shuttle conveyor option that accepts molds not produced on bottom boards.

Four Types of Linear Mold Handling Systems

Type I System

- Single row pouring line - Cooling times up to 30 minutes

Type II System

- Double row combined pouring and cooling line - Cooling times up to 45 minutes

Type III System

- Triple row combined pouring and cooling line - Cooling times up to 1 hour

Type IV System

- Single row pouring plus triple row cooling line - Cooling times in excess of 1 hour