Molding Machine

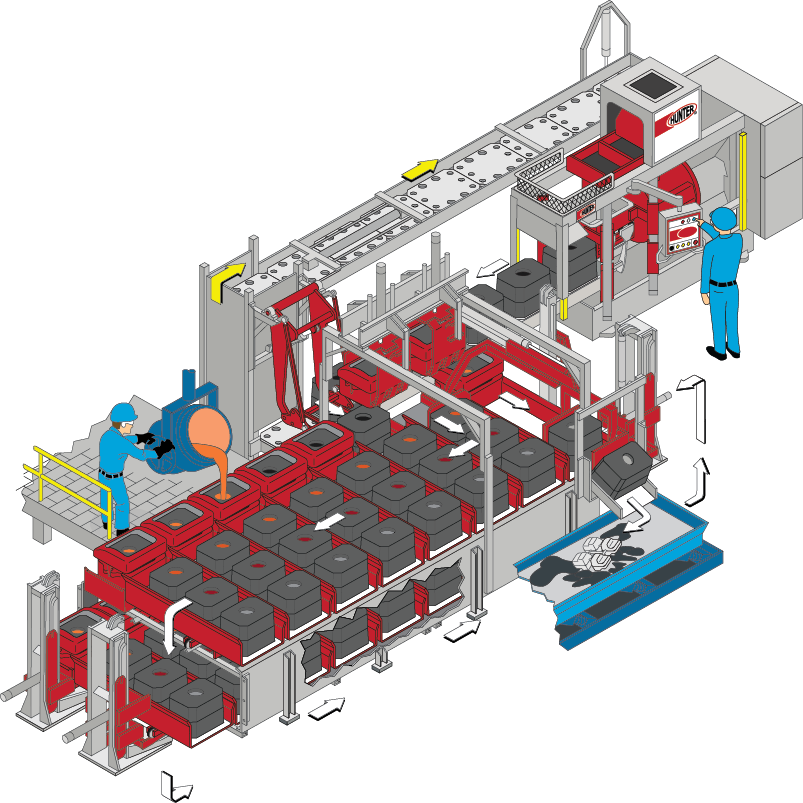

Hunter re-designed the HMP to produce the XL. The XL line enables our customers' foundries to work more efficiently, while producing highest-quality, near-netshape castings in less time than ever before.

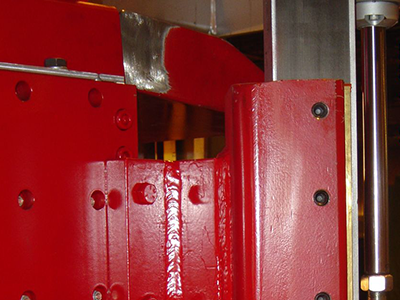

- Pins and bushings maintain perfect alignment of the cope and drag flasks during mold squeeze and draw.

- Linear guiding system glides effortlessly on the hardened stainless steel pillar guides.

- The entire system of cope and drag flasks and platen are held in precise alignment eliminating mold shift.

- AutoLock Quick Pattern Change System, with hydraulically operated piston-style clamping, eliminates pattern bolt down time allowing faster pattern changes.

- Inverted hose tracking system organizes all hoses and wiring from the drag and cradle out of the operator's way allowing unhindered access for pattern changes and setting ram-ups and chaplets.

- Redesigned operator stations with movable controls on both sides of the machine.

- State-of-the-art interface on the front side of the machine provides multi-language control of the molding cycle.