We design our mold handling systems to meet each customer’s exact equipment, production and foundry floor specifications. And our HV Turntable reduces labor; improves air quality and working environment. Which is why there are more than 300 Hunter Turntable Systems in operation, used with all types of molding machines, all over the world. So even if you’re not running a Hunter molding machine, chances are, we’ve got the mold handling solution that’s right for your application.

Types of Verticle Turntables Systems

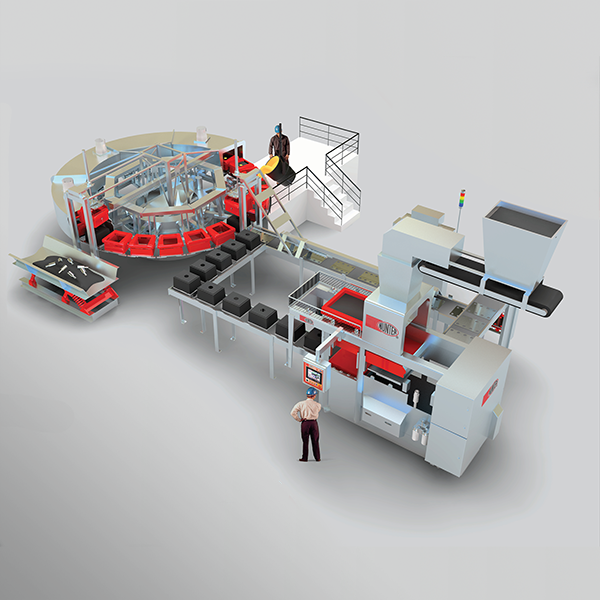

Single-Level Verticle Turntable System

Single row pouring line - Cooling times up to 30 minutes

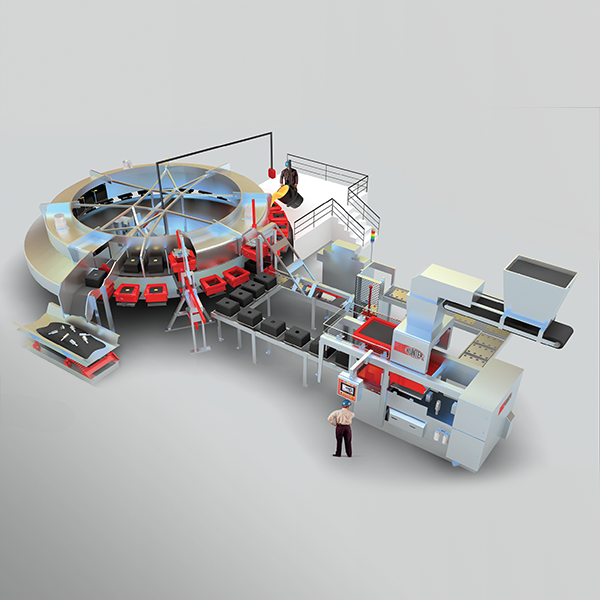

Dual-Level Verticle Turntable Systems

Molds are elevated and pushed onto level 2

Cooling times up to 45 minutes

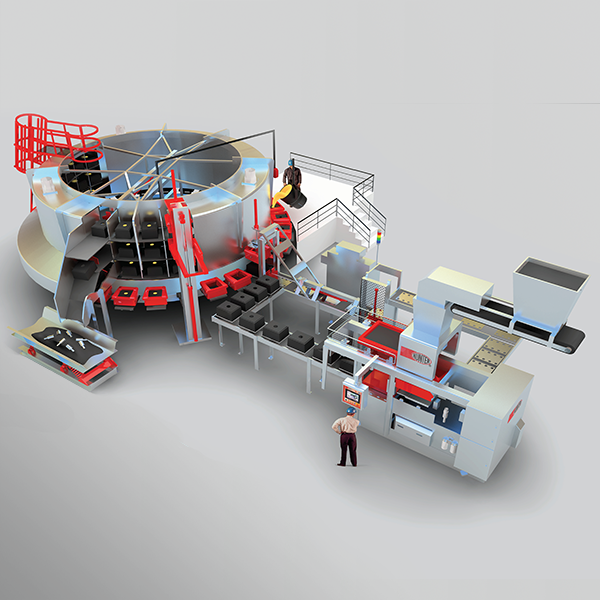

Multi-Level Verticle Turntable Systems

Molds are elevated and pushed onto levels 2, 3 and/or 4

Cooling times up to 1 hour